Study to Streamline Management at Koishiwara River Dam

Menu

Study to Streamline Management at Koishiwara River Dam

Koishiwara River Dam is under construction on the Koishiwara River, part of the Chikugo River system. The dam is being built to reduce downstream flood damage through streamflow regulation and to secure water volume to meet increasing water demand (agricultural, industrial, and domestic water supply). It is approximately 139 m high and 550 m wide (crest length), with a reservoir area extending about 1.2 km².

Since the dam was constructed, signs of abnormality have been detected from daily inspections. For civil engineering structures such as the dam body and inspection gallery, inspections include visual inspection for any water leaks and cracks, as well as measurements of osmotic pressure, water quality, etc. Also, it is important to understand the condition of the facility when construction began and how it has changed over time, and to take preventive measures, just as daily and regular inspection results must be recorded as systematic electronic data on an ongoing basis. Therefore, in order to properly maintain dams and other large structures, such data must be centrally managed to remain accessible.

With the aim of improving the efficiency of operation and maintenance of Koishiwara River Dam from initial filling until dam operations, this project developed a construction information management (CIM) system for dam O&M. Additionally, various possible ICT were also tested for use at Koishiwara River Dam.

Rendering of Koishiwara River Dam

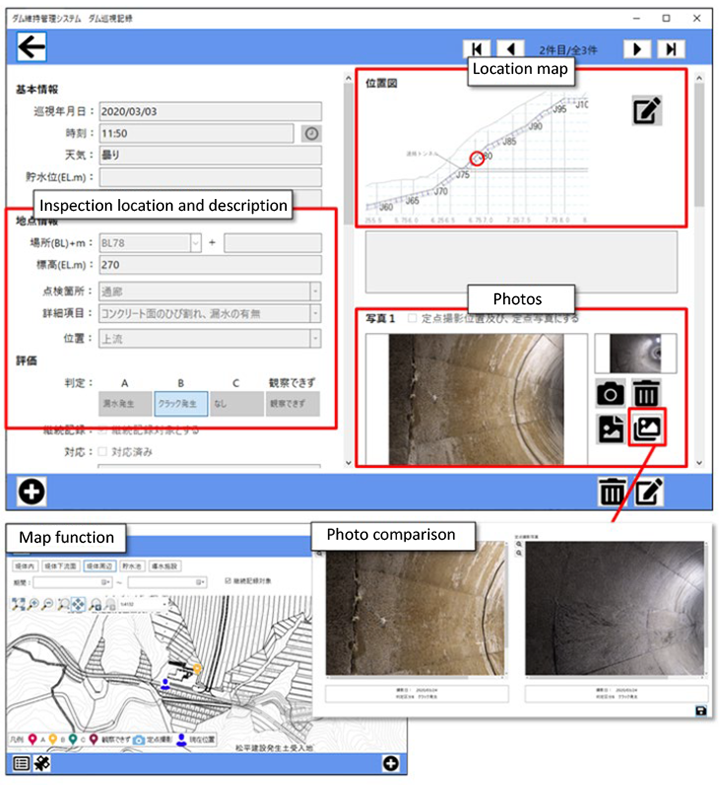

To streamline O&M, a tablet system was established to record daily inspection results around the inspection galleries, dam body, and reservoir. Using tablet functions (digital input, camera, GPS) has made field recording easier, also enabling location data to be associated with text and photo data automatically when recorded.

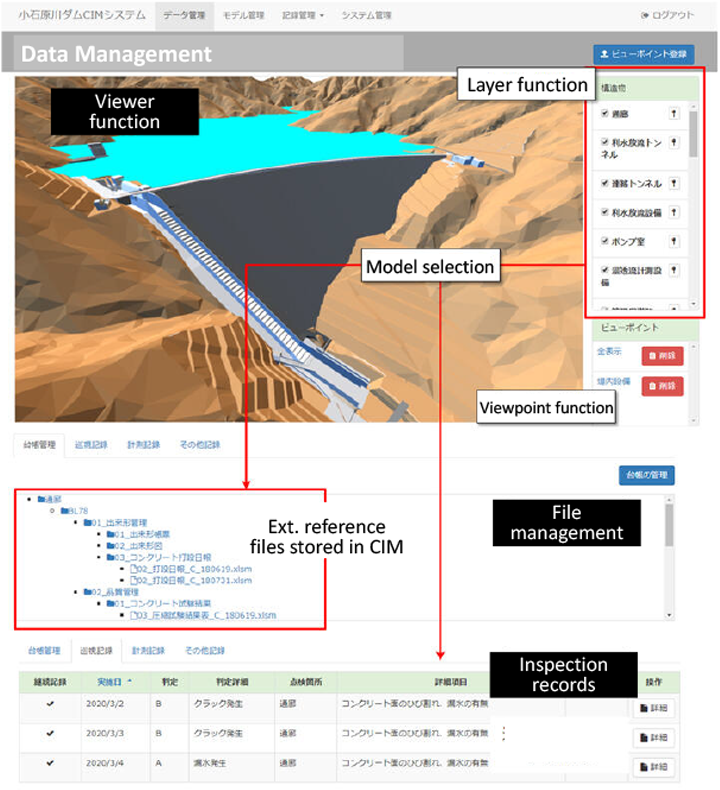

Daily inspection data recorded with this tablet system is stored on the cloud-based CIM system. The CIM system centralizes and manages the O&M data. Quality control (QC) data at the time of construction is stored along with 3D models, and measurement results from dam measurement equipment are also stored. Once operational, daily inspection records for the dam are plotted on the 3D model of the dam facility, allowing the user to view and interact with the data through an intuitive interface.

In order to utilize ICT to further streamline daily inspection work in the inspection galleries, a field verification was conducted together with Terauchi Dam, using Bluetooth low energy (BLE) beacons to obtain current location data and using unmanned aerial vehicles (UAVs) to photograph the facilities.

Input screen of the CIM system

Inspection results plotted on the 3D model

Project Details